May 13, 2025

From Local to LIGNA

About System TM’s new look, showcasing trusted quality and building living spaces

Von Aislinn Esterle

Let us tell you a little story about a Danish machine producer that set out to change solid woodworking. Today, System TM is a leading global producer of high-performance timber processing systems for the solid wood industry and will be exhibiting together with HOMAG in Hall 14 at the world’s largest woodworking industry trade fair – LIGNA 2025.

It was 1977 when Poul Thøgersen founded Thøgersen Maskinfabrik (TM) as a family-owned, local machine manufacturer to make manual woodworking easier, using the insurance money he received from a work-related accident. Meanwhile, the LIGNA trade fair in Germany entered its second edition, exceeding all visitor expectations and making waves in the field of accident prevention. Since then, System TM has gradually grown into an internationally recognized manufacturer of system solutions that optimize both staff and wood resources, and has joined the German HOMAG Group. In the meantime, LIGNA has become a leading trade fair for the global woodworking industry.

We are moving

LIGNA is an important platform for us to connect with our customers and prospects from around the world. We relish the opportunity to showcase our equipment and share our passion for optimizing staff and wood resources with the solid wood community, making our machines accessible to customers who might not otherwise be able to see them in action.

After two decades of exhibiting in Halls 12 and 27, we are ready to try something new this year. Not only have we changed our logo and company colors, but we are also moving into Hall 14 to officially join the HOMAG family.

Since LIGNA is one of the most important trade shows in the industry, we knew we had to level up again. And that is exactly what we are doing for the anniversary edition this year! Visitors can look forward to two best-practice machine concepts for optimizing staff and wood resources, including a wide range of scanning equipment from our scanning partner MiCROTEC. This has not been seen at any trade show in the world for more than six years. So, expect us to make some noise! The icing on the cake is that they will be shining in brand new colors, with our new machine design making its debut at LIGNA 2025.

Automated optimization

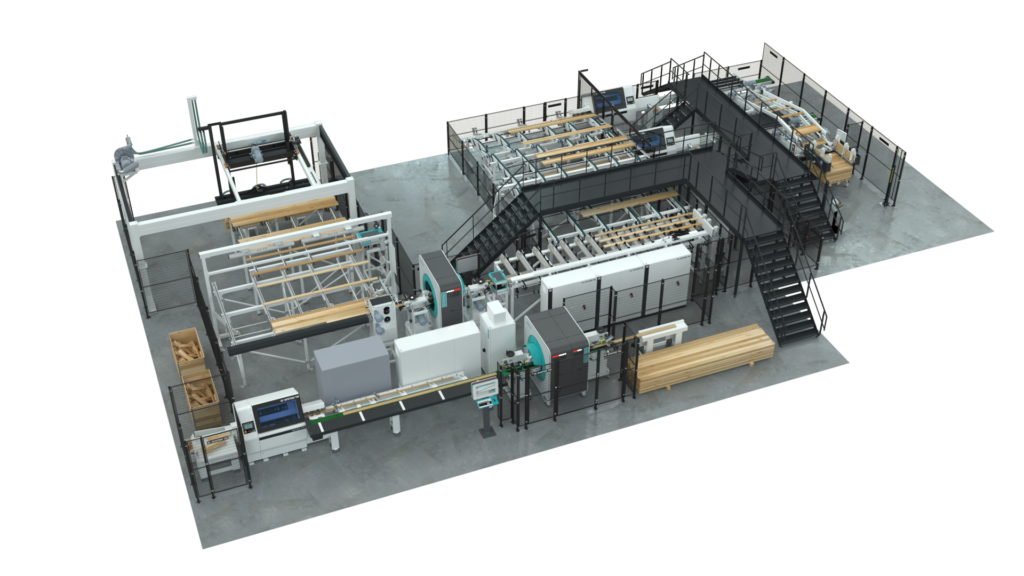

We are ready to turn up the volume on HOMAG’s home turf with a fully automated timber processing line to demonstrate our optimization and automation abilities. It consists of an automatic infeed system model Opti-Feed 6000 Vack, no less than two high-speed cross-cut saws model Opti-Kap 5103 and one of our most successful stacking systems model Opti-Stack 3000.

Run by a single supervisory operator, the solution starts with a vacuum de-stacking unit that feeds workpieces into the line, which are then automatically moved through a series of scanners to collect data for optimization.

The power of wood scanning

In partnership with MiCROTEC, we will showcase a range of advanced scanning equipment including Endscan, Viscan, Warpscan, M3 Scan moisture meter and a Goldeneye multi-sensor quality scanner. MiCROTEC’s AI-powered solutions identify wood characteristics accurately and at high speed, increasing production yield and grading accuracy. All of these innovative scanning solutions can be seamlessly integrated into a System TM Opti-Solution, ensuring the best production optimization at high capacity.

Cross-cut automation

After scanning, the workpieces are realigned and collected in batches before entering the two Opti-Kap 5103 optimizing cross-cut saws. The saws automatically cut the workpieces into fixed length components. The fixed length workpieces are then transferred to an Opti-Stack 3000 automatic stacker and stacked on a pallet in a herringbone pattern with stabilizing sticks. The off-cuts from the cross-cut process are blown out through the saw’s waste gates.

Full speed for high capacity

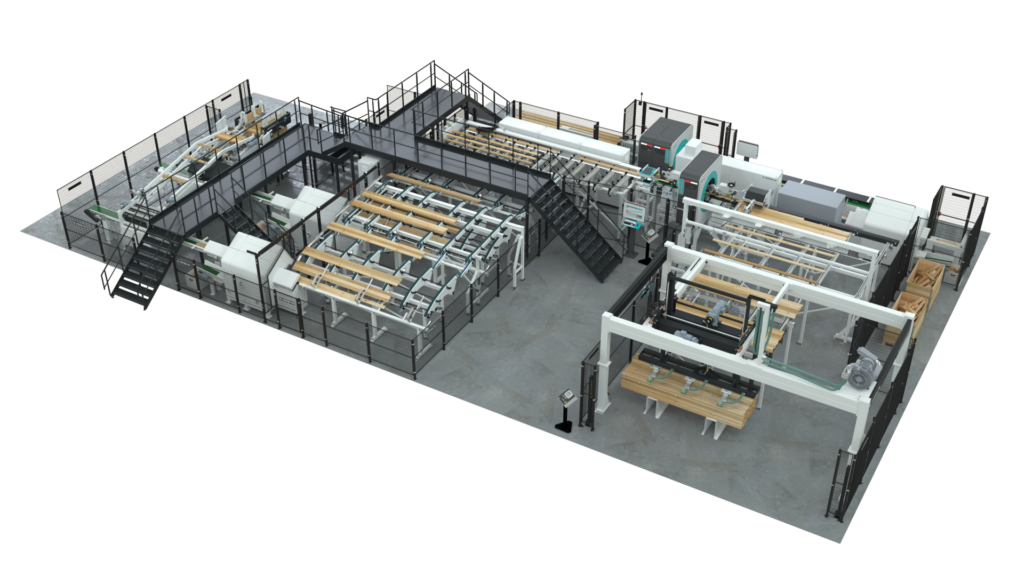

In addition to our fully automated Opti-Solution, we will show a smaller cross-cut line to emphasize optimal wood utilization and high cross-cutting capacity. This line includes a MiCROTEC Goldeneye multi-sensor scanner with X-ray module and laser technology, capable of detecting defects on all four sides of the workpiece and optimizing them into different product types.

This demonstration illustrates the effectiveness of MiCROTEC’s scanner when integrated with our intelligent cross-cut saw. The workpieces are automatically cut to size based on the scanner data and optimized by the saw’s software. This setup allows us to show different scenarios of cutting out defects detected in relation to the wood quality.

Building living spaces.

Together with HOMAG, Weinmann and Kallesoe, System TM will for the first time be showcasing our expertise in timber processing in Hall 14, underlining our solid wood competence for the future.

Under the motto “Building living spaces”, the HOMAG Group will combine years of know-how in close cooperation to demonstrate the power of designing sustainable living spaces, covering the entire value chain with compatible solutions.

Join us in Hall 14 to help us rock the house and find out how a HOMAG solution can take your business to the next level!